On Track for Sustainability

Old Rails Point the Way to Net Zero

With Gebäude X in Zurich, the firm Gigon Guyer reinterprets sustainable construction: a commercial building made from disused railway tracks that drastically reduces grey emissions and stands as a symbol of urban transformation toward a circular future.

Sui binari giusti, testo in italiano

With the introduction of SIA Standard 390 “Foundations for Sustainable Construction” in 2014, the Swiss Society of Engineers and Architects marked an important milestone for sustainable building in Switzerland. The standard provides clear guidelines for systematically integrating ecological, economic, and social criteria into planning and construction processes. A central component of the updated SIA 390/1:2025 is the set of specific target values for greenhouse-gas emissions in kg CO₂-eq/m²/year, differentiated by building category as well as between new builds and refurbishments. For example, in the residential sector the target values for the construction stage of new buildings are 9.0 kg (baseline target) and 6.0 kg (ambitious target), and for refurbishments 5.0 kg and 4.0 kg respectively. Through a continuously adjusted reduction pathway, these values are intended to lead to net-zero buildings by 2050.

In this context, the Swiss Federal Railways (SBB) sought an especially sustainable solution for an urban commercial building in the competition for Building X. An exacting limit of a maximum of 5 kg CO₂-eq/m²/year was set for embodied energy-related emissions. Since this is scarcely attainable with conventional construction methods, alternative design and construction approaches were required. In particular, the reuse of building components offers considerable potential, as emissions incurred in earlier life cycles do not have to be accounted for again.

At the conclusion of the two-stage competition, the team of Gigon Guyer Partner Architekten prevailed with an idea as simple as it is convincing: a house made of rails for the Swiss Federal Railways—both identity-forming and innovative in its treatment of embodied energy. By reusing decommissioned rails—available in large quantities and deployed as load-bearing elements of the building structure—a substantial share of embodied CO₂ emissions can be saved. The competition jury praised the project as a “carefully curated re-use project” that achieves an appropriate architectural expression while functioning as an innovative building block within the ensemble.

The following article examines how consistent material reuse, the reduction of embodied energy, and innovative structural design give rise to a forward-looking building with city-shaping impact.

Urban Context

Building X forms part of the Werkstadt Zürich development plan, in which the SBB site between the main station and Altstetten is being transformed step by step into a mixed-use urban quarter. The competition brief called for an elongated seven-storey volume along Hohlstrasse, with a head building and a northward cantilever, aligned with the site’s master plan. As the first new building on Hohlstrasse, Building X assumes a signalling role in this transformation—from a closed workshop compound to an open “work-city” of urban production, the creative economy, and culture. In urban terms, the building mediates between differing contexts: towards the urban Hohlstrasse to the south, it presents an active public frontage, while to the internal service road, Hohlgasse to the north, it relates to the site’s industrial logic.

Resources, CO₂ Balance, and Circular Logistics

At the heart of Building X is a carefully conceived structure made from decommissioned railway rails. In total, around 12 kilometres of rails from the SBB materials depot were earmarked for the columns and beams of the main storeys. These standardised steel profiles of the Swiss Federal Railways, with their high strength and consistent quality, offer ideal conditions for a second service life. At the same time, the distinctive profile—visibly rust-red and bearing traces of use—anchors the building both metaphorically and aesthetically in the site’s industrial history.

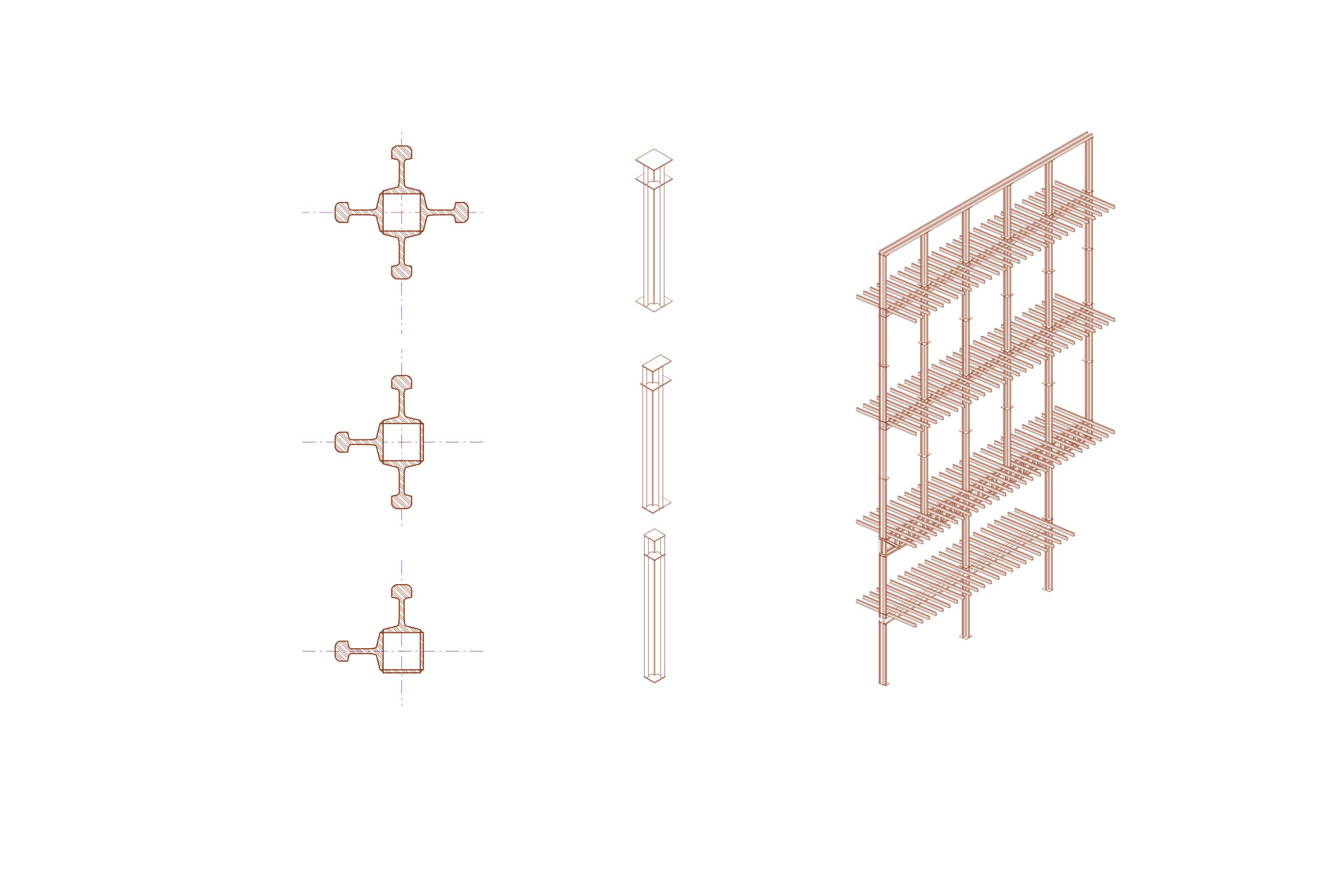

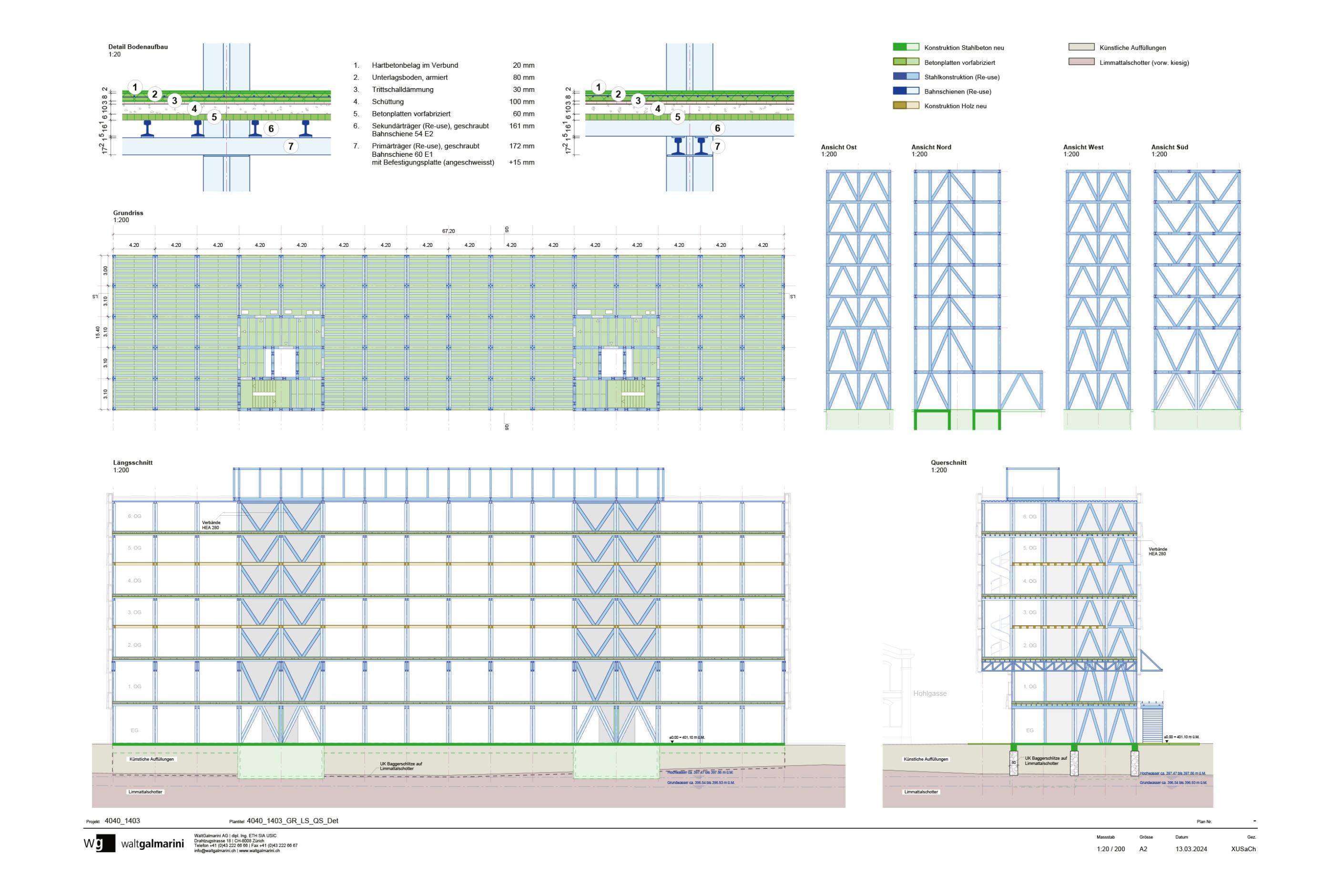

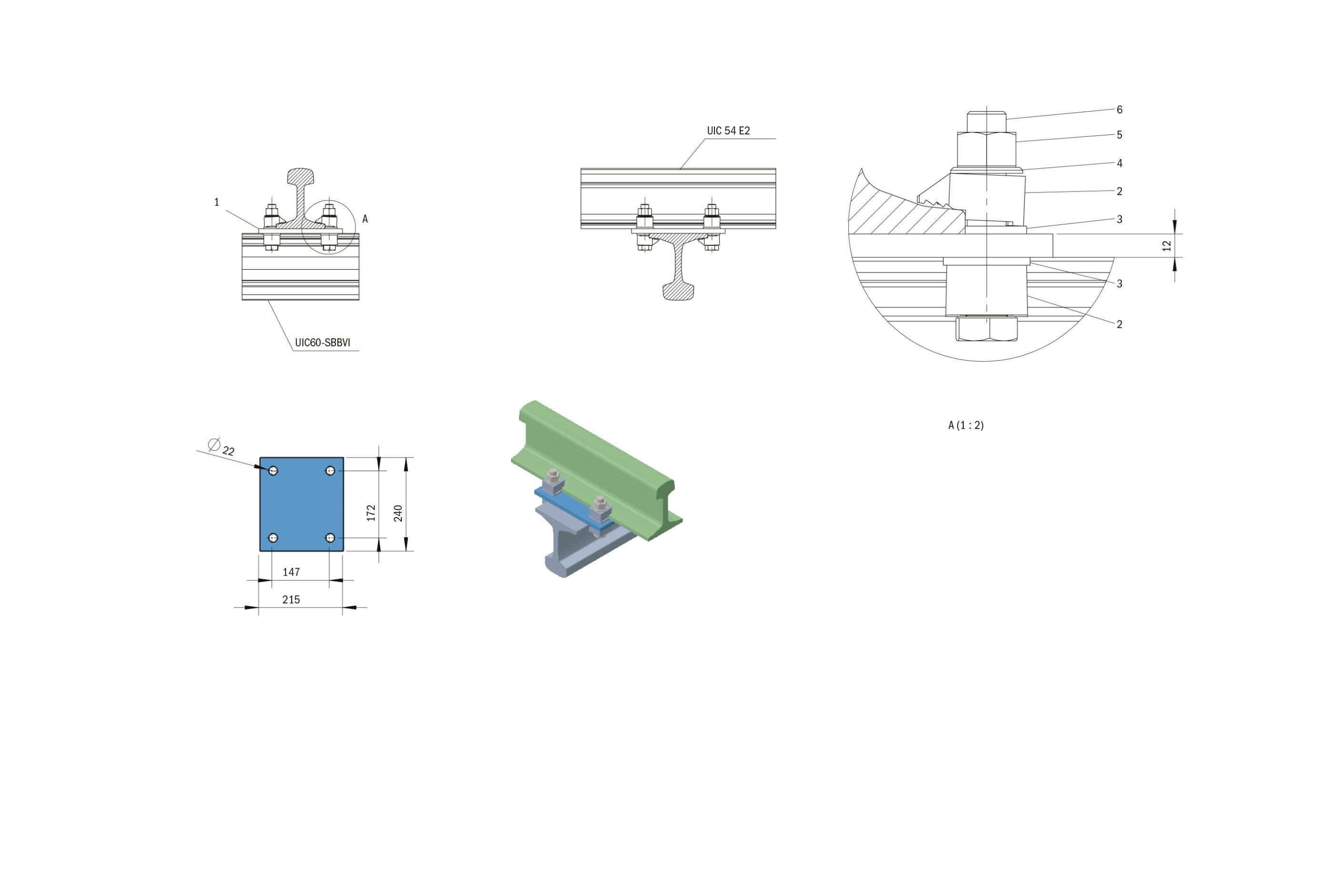

The six-storey commercial building is conceived as a classic skeleton frame with a column grid of 4.2 × 3.1 m. In the longitudinal direction, old UIC 54 E2 rails span as joists at approximately 50 cm centres across the 4.2 m bay. Above them lie prefabricated reinforced-concrete slabs 6 cm thick which, together with a granular fill and a fine concrete topping, form the floor slab. This assembly can carry imposed loads up to 15 kN/m² and simultaneously acts as a diaphragm. Every 4.2 m, the rail joists bear on primary beams running transversely: for these, two parallel UIC 60 E1 rail profiles are used, spanning 3.1 m from column to column and installed as continuous beams over multiple bays.

The columns are formed from four UIC 60 profiles welded together into a bundle. For interior columns, this creates a solid square section that provides sufficient buckling resistance at mid-storey. At the bearing points of the primary beams, two of the four rails are locally omitted so that loads are carried via the remaining profiles. Edge and corner columns are accordingly composed of half or three-quarter sections to align with the façade. Welding is executed only in segments according to structural requirements—minimising material and energy input during fabrication.

Horizontal stability is provided primarily by the two stair and lift cores: they are formed as steel frames using reclaimed profiles, with diagonal bracing within the core walls. These steel core structures are made from deconstruction steel and clad with gypsum-fibre boards for fire protection. In this way, the vertical circulation zones meet the fire-resistance requirements yet remain demountable.

Despite the high proportion of exposed steel, the structure satisfies fire-safety regulations through an integrated concept. The building is equipped with a sprinkler system, which allowed the required fire-resistance duration of the primary structure to be reduced to R 30. Owing to their moderate structural utilisation, the rail-steel beams and columns already meet this 30-minute rating in an emergency. Thanks to sprinkling, the steel elements can remain untreated and require no intumescent coating—a gain for resource efficiency as well. The connections in the rail structure are designed as bolted joints. Rail segments and steel beams are thus only spot-welded in the workshop and bolted together on site, enabling all elements to be separated by material type at end-of-life and returned to the material cycle.

The major challenge of such circular architecture lies in planning the procurement and processing of all components. The decommissioned rail profiles are collected at SBB’s Railway Technology Centre in Hägendorf and provided in sufficient quantities. For the steel construction of the cores and the ground-floor girders, profiles from deconstruction were sourced via Eberhard; a corresponding letter of intent for acquisition was already in place during the competition.

Structural Strategies for Reducing Embodied Energy

The current sustainability discourse in architecture and construction is shifting its focus from operational energy to embodied energy and the CO₂ emissions incurred during construction. As a result, established standards regarding material selection, structural performance, and architectural measures are being critically reassessed. A particularly conspicuous paradigm shift in sustainably conceived projects is the deliberate reduction of spans in favour of denser column grids. Whereas spans of around seven to nine metres were long common to ensure flexible layouts with a minimum of columns and maximum freedom of use, contemporary building concepts intentionally employ closer spacing of load-bearing supports. Even moderate reductions in span lead to significant material savings and thus to a substantial decrease in embodied energy. Larger spans—traditionally realised in steel or reinforced concrete—by contrast, cause higher emissions due to greater material use and more complex, resource-intensive construction.

An exemplary case of this new approach is SBB’s Building X in Zurich, conceived as a frame structure with a compact column grid of 4.2 × 3.1 metres. The Hortus office building in Allschwil by Herzog & de Meuron follows the same strategy, deliberately adopting a tight grid of 5.6 × 2.8 metres with load-bearing elements in BauBuche (LVL) and timber–earth composite floor slabs to enable an environmentally responsible construction. This structural shift to improve life-cycle performance is closely linked to a reassessment of the spatial dimensions considered socially necessary to ensure functional flexibility. Whereas spans of seven to nine metres were once the standard for maximum flexibility, these projects now demonstrate how spans of four to six metres can deliver flexible spatial concepts more sustainably.

In parallel, there is a clear trend away from traditional in-situ construction towards industrial prefabrication. After the experience of the post-war years and a reversion to conventional on-site methods following the oil crisis, it is once again evident that cast-in-place techniques—owing to complex formwork, weather-related delays, and inefficient material use—entail higher emissions. Prefabrication, by contrast, enables more precise production, shorter construction times, lower emissions and waste, and higher quality standards. Projects such as Building X in Zurich and Hortus in Allschwil combine modular prefabrication with innovative structural concepts to realise sustainable and circular construction methods.

Building X stands as an exemplar of a paradigm shift in our building culture. Resources are no longer consumed but reused; urban design, structure, and material are conceived holistically and designed in sync. For architects, the project reveals the latent potential in existing components—and the new aesthetic expressions that can emerge from their reuse. Building X may only be the beginning, but it already offers valuable answers to pressing questions of sustainability—because the future of building is circular.